Technical Specifications

| Size Range

NPS2″-40″/DN50-1000mm |

Main Material

Carbon steel, Stainless Steel, Aluminum Bronze, Duplex steel etc. |

| Temperature Rating

Soft Seat: -29 ~ +200°C |

Stem material

Stainless steel |

| Pressure Rating

0.6Mpa I.0Mpa 1.6Mpa 2.5Mpa 150LB |

Directional /Stem Type

Bi-directional, Uni-directional /Rising Stem |

| leakage level

Soft seat: Zero Leakage |

Body Style

Wafer |

| Disc Material

Stainless steel, Duplex steel etc. |

Flange Drilling

ASME B16.5, EN1092, GOST 33259, BS etc. |

| Seat Material

Soft Seat: NBR, EPDM, PTFE, Viton etc. |

Port Type

Reduce Port,V type Port etc. |

| Design Standard

MSS SP-81, MFR Standard |

Test Standard

MSS SP-81, MFR Standard |

| Face to Face

MSS SP-81, MFR Standard |

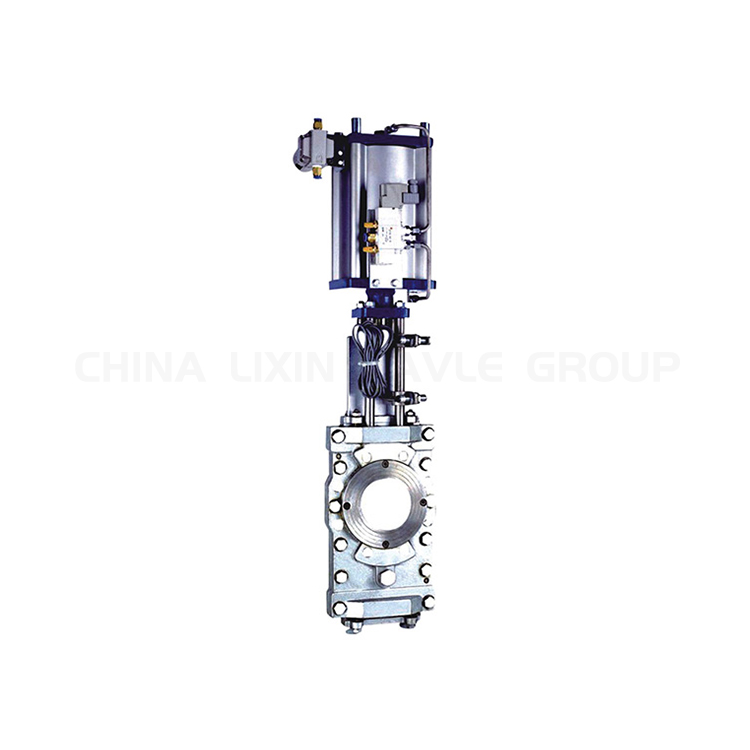

Operation

Handwheel, Worm Gear, Electric, Pneumatic, etc |

| Application

Power, Pulp & Paper, Carbon Black, Chemical, Granular slurry, mud etc. |

|

| Other

The carefully selected materials and contemporary design make our knife gate valve highly recognized. If our knife valve cannot meet your choice, we can provide you with special made. |

|

Chief Features

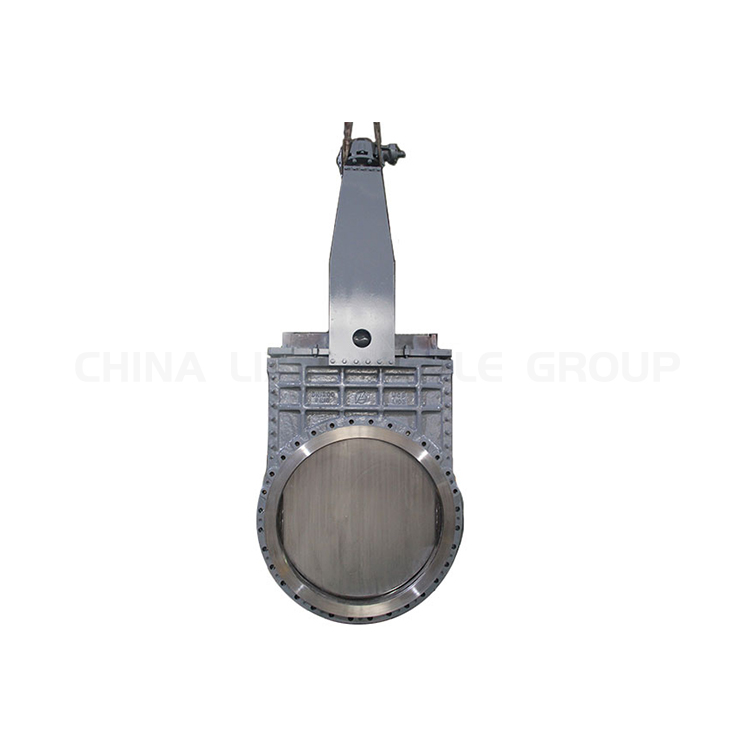

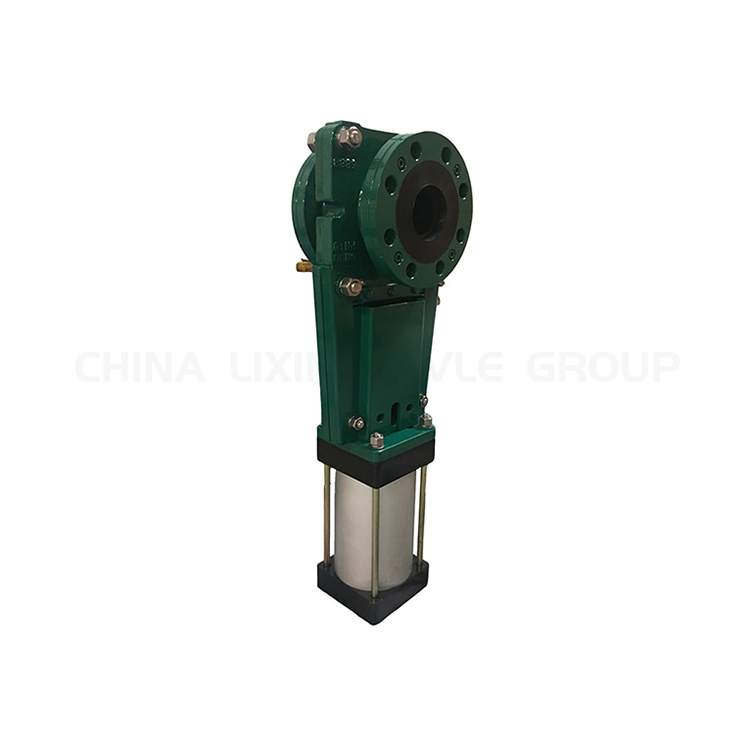

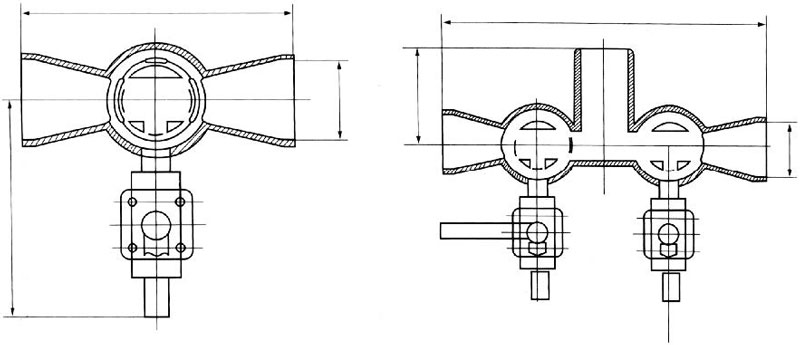

Ultra-thin design, beautiful appearance, light weight and compact structure, easy to install and use.

The valve is connected by clip-on, and the structure length is short, which can reduce the weight of the entire pipeline system.

Soft and metal combine seat, flexible metal seat ring insert soft rubber ring, zero leakage.bi-directional.

Two sides of valve bottom have space for accumulations,avoid knife can’t shut to bottom.

Flush ports and drain ports design,easy to remove accumulated medium

Bonnet type with middle Guide sealing block,to prevent slag entering into cover cavity

Acid and corrosion resistance, providing the service life of the valve