Technical Specifications

| Size Range

NPS1/2″-24″ / DN15-600mm |

Main Material

Carbon steel, Stainless Steel, Aluminum Bronze, Duplex steel etc. |

| Temperature Rating

-29 ~ +100°C |

Stem Material

Stainless Steel |

| Pressure Rating

I.0Mpa ~ 11.0Mpa 150LB ~ 600LB |

Leakage Level

Zero Leakage |

| Plug Material

Carbon Steel,Stainless steel,Duplex steel etc. |

Flange Drilling

ASME B16.5, EN1092, GOST 33259, BS etc. |

| Seat Material

NBR |

Port Type

Full Port |

| Design Standard

API599, API 6D, ASME B16.34 |

Test Standard

API 598, EN12266-1, ISO 5208 |

| Face to Face

API 16.10, EN558-1, API 599 |

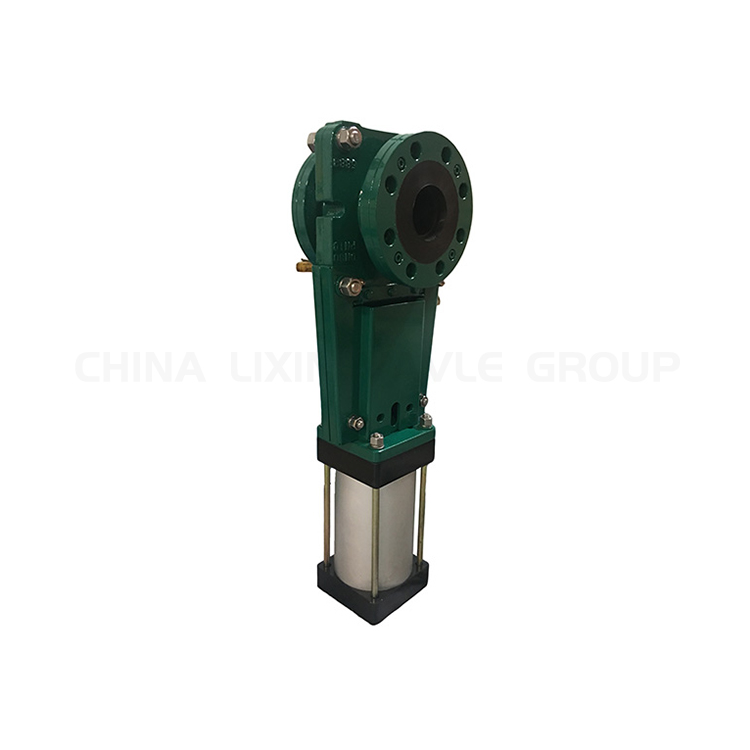

Operation

Lever, Worm Gear |

| Application

aviation kerosene, crude oil, light oil, natural gas, liquefied gas, pipeline gas, chemical medium and other pipelines as cutoff medium |

|

| Other

The carefully selected materials and contemporary design make our plug valve highly recognized. If our Plug Valve cannot meet your choice, we can provide you with special made. |

|

Chief Features

During the opening and closing of the valve, the sealing surface of the valve body has no contact with the sealing surface of the sliding vane. Therefore, the sealing surface has no friction and wear, the service life of the valve is long, and the opening and closing torque is small

During the maintenance of the valve, it is not necessary to remove the valve from the pipeline, but only to remove the valve bottom cover and replace a pair of slide plates, which is very convenient for maintenance;

The valve body and plug are full port, the medium has no flow resistance when passing through the valve, and the pipe can be cleaned through the ball, which overcomes the shortcomings of the reducing valve;

The valve is equipped with relief device (optional) to prevent abnormal pressure rise in the valve chamber and check the effect of the valve after the valve is completely closed;

The sealing of the valve is achieved by the sealing ring around the valve. It has particular protection of swallow-tailed sink and fixed sealing rings.

Operation Principle

When the plug valve is fully open, the channel is in alignment with the channel of valve body,which can ensure ideal and lowest pressure drop.

When the handwheel is turned,the plug will rotate toward the closing direction,and at the same time draft the rotation of the valve disc by 90°.When the handwheel is turned further on,the plug will pressured down,and make the valve disc open to two sides,so that the valve disc will be firm contact with the valve seat and close the valve.

When the handwheel is turned inversely,first of all the plug will move upward,and the valve disc and valve seat will be separated,second the handwheel shall be turned further on,till the valve disc is turned by 90°driven by the plug,finally the channel of plug will be in alignment with the channel of valve body,the valve is fully opened.