1 The detailed valve and pipe flange installation method are as follows

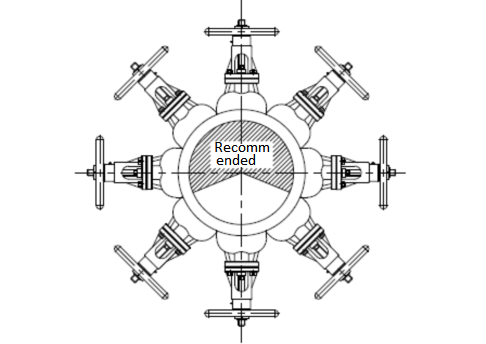

2 The position of the valve installation pipe is as shown in the figure below (the valve can be installed in various positions, but we recommend using it in the most suitable position):

3 The valve can only be installed in one direction. The direction of the sealing ring is consistent with the flow direction of the medium. The user must confirm the flow direction of the medium and install the valve in the direction of the arrow on the valve body.

4 After the flanged valve is welded and installed on the pipe flange, do not install the valve immediately. The pipe work can only be carried out after normal temperature. It is absolutely forbidden to weld the pipe after the valve is installed on the flange;

5 When installing the valve, you should consider the convenience of operation, and install the valve in an easy-to-operate place as much as possible;

6 Tighten the bolts on the flange according to the above installation method. The pipe bolts should be tightened diagonally. Be careful not to tighten unilaterally. Unilateral tightening may cause leakage;

Note! It is advisable to use proper force when screwing the fastener bolts to achieve a complete seal between the flange and the valve.